MID-POWER LED Comparison : Seoul 3030C vs SAMSUNG LM301 B/H

Before hortiONE released the first product, we created numerous prototypes and carried out tests with different LEDs on the 3030 platform. Seoul and SAMSUNG provided the best performance on this platform. That’s why these two types have been reviewed and tested in more detail.

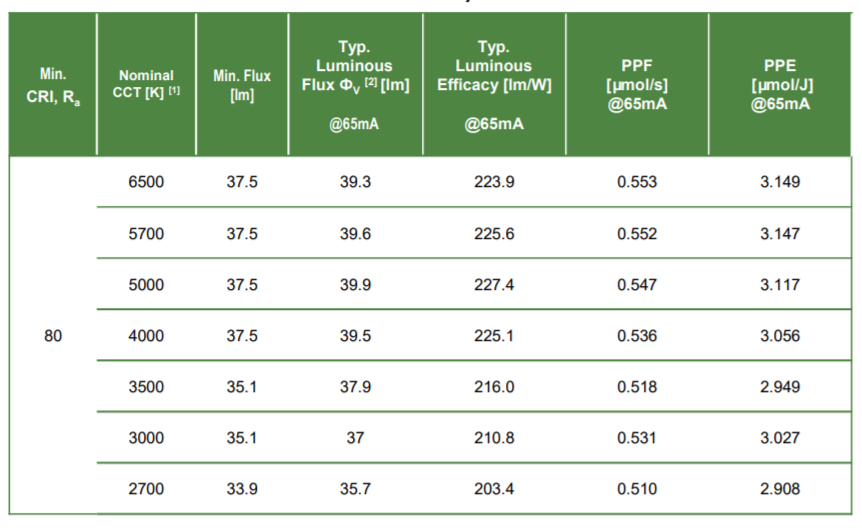

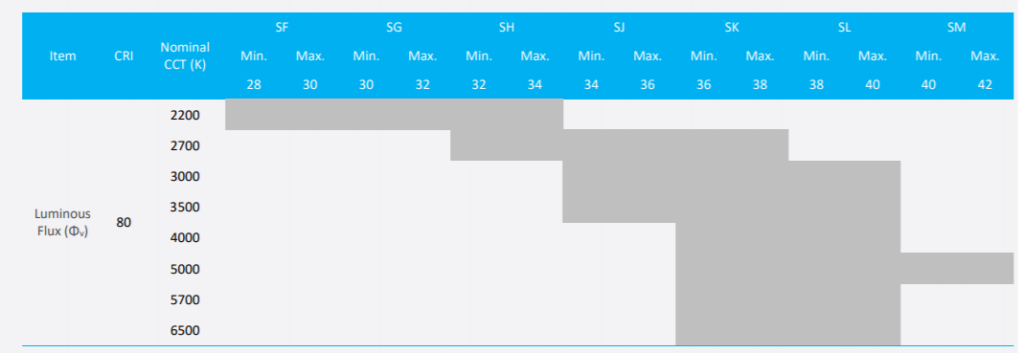

Performance Comparison

The Performance and Efficacy (µmol/J) are quite similar. It mostly depends on the LED revision and development state.

An important side-note: the 6500K variant (cold white with a high portion of blue) is always the most efficient LED. Therefore do not get misguided by values of up to 3.1µmol/J as this is only true with 6500K @65mA. Also, such values never include the loss due to the LED-Driver.

hortiONE mixes 3000K and 4000K to achieve the final 3500K. Also, we add the highly efficient HIGH-Power OSLON® Square Hyper Red (660nm) LED with an efficacy of up to 4,4µmol/J. This combination supports Chlorophylle a/b and directly triggers the phytochrome r.

Note: A higher amount of Hyper-Red is often used to increase the efficacy.

Summary: Due to very similar performance, we further tested the longevity and chemical resistance. As the light output should remain stable over time in order to achieve stable production performance.

A big Problem: Chemical restistance of LEDs Sulfur and VOCs

Some volatile organic compounds (VOCs), above all sulfur (S) and hydrogen sulfide (H2S) are chemicals that cause sensitive damage to LEDs (Light Emitting Diodes). Due to its high reflectivity, silver is often used as a reflector material. VOCs cause it to corrode and it is converted to silver sulfide (Ag2S). The black crystal structure of Ag2S reduces the reflectivity which can lead to a decreased light output of up to 30 – 40%.

SSC used a patented packaging technology https://patents.google.com/patent/US20130214298A1/en to avoid sulfur sulfide formation in order to increase the lifetime, reliability, and chemical resistance. One very important improvement against the corrosion of silver is the use of Titanium Oxide (TiO2) alloy above the Silver as protection. This technique is used by SEOUL 3030C and SAMSUNG LM301B/H LED Chips.

Soeuls internal tests (IEC standard) and a simplified test

The below article was previously posted and shows Seoul’s internal lifetime, humidity and chemical resistance test as well as a comparison with unknown manufacturers

Sulfur Resistance – Why Seoul 3030c?

hortiONE Test using HOTBOX Sulfume a sulfur vaporizer

We aimed to add a practical approach using a sulfur vaporizer (Hotbox Sulfume sulfur vapouriser, https://www.hotboxworld.com/products/hotbox-sulfume/8/cat ) LED Panels using different LED Diodes from the same kind (MID-Power, 3030) but different manufacturers were installed in a 60x60cm grow Tent. The Test was conducted with varying temperatures for 10 weeks 8 hours per day. The lights were powered on and faced towards the sulfurizer. Note, those are test conditions and not the intended way to use the Hotbox Sulfume. Culturists use Sulfur as a preventive fungicide against powdery mildew, rose black spot, rusts, Botrytis, and other diseases. Sulfur prevents fungal spores from germinating. That’s why this test aims to be a practical approach for long-term use of a sulfur vaporizer and with an indication of long term VOC corrosion effect

Test condition:

- Varying Temperature

- ~30g Sulfur – vaporized in a HOTBOX Sulfume

- 250h – 8h per Day

- 3 different LED-Panel: All LED Board where using constant current LED Driver at a real consumption of 30W

- hortiONE 368 V2 (standard model using Seoul 3030C and Osram, Oslon 660nm HP)

- hortiONE prototype – different LED Diodes with the same platform but a different manufacturer

- Variant LED Panel Soul 3030C, Osram Oslon HR inc a protective varnish (ELPEGUARD® SL 1307 FLZ/2)

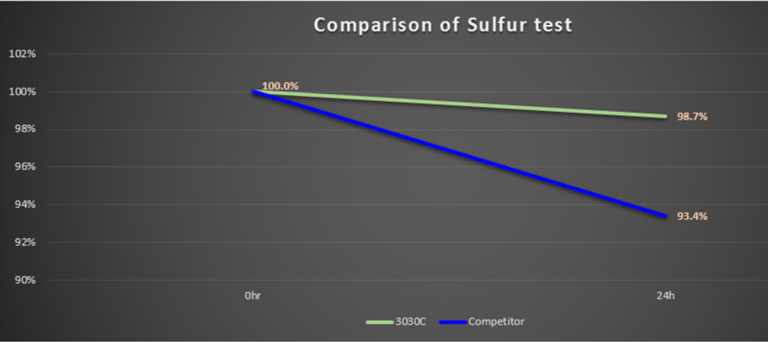

Resuslts of the Sulfur Test

After the Test, both panels have been cleaned, firstly with the use of particle-free Air and then with the use of Isopropyl-Alcohol.

To our own surprise is the result evidently clear. This is surprising as both chips use Titanium Oxide (TiO2) alloys to prevent the silver from corrosion.

While the Soul 3030C LED Chips to remain almost unchanged the SAMSUNG LM301B/H shows the formation of SilverSulfide (Black spots) which leads to a significant loss in light output and efficacy.

As sustainability and quality matter a lot to us, we are happy about the decision of SEOUL LED-Chips.

Relevant Links, Sources and further Information

- https://dammedia.osram.info/media/resource/hires/osram-dam-3813126/Chemical%20compatibility%20of%20LEDs.pdf

- https://cdn.samsung.com/led/file/resource/2019/06/Application_Note_Guides_on_Chemical_Compatibility_Rev.0.2.pdf

Effective Solution to Prevent Degradation of LED Systems Due to Sulphur and Chlorine Compounds

- hortiONE: Why Seoul 3030C